Qingdao Longchangjie Machinery Co., Ltd. is an important enterprise in the field of plastic machinery manufacturing in China. Its winding pipe production line is renowned for its advanced technology, unique process and excellent product performance, especially holding a leading position in the field of large-diameter winding pipe equipment. The company was formerly known as Qingdao Changjie Machinery Co., Ltd., which was established in 2000. Through over 20 years of technological accumulation, it has formed the ability to research, develop and manufacture a wide range of winding pipe equipment and related products, and its products are widely used in municipal, agricultural and industrial fields.

Core winding pipe production line types and technical parameters

HDPE large-diameter hollow-wall winding pipe production line

Technical positioning: The result of the national "15th Five-Year" key scientific and technological research project, developed by introducing and absorbing advanced foreign technologies, it is the company's flagship product and has the highest sales volume in the same industry in the region.

Capacity and specifications: It can produce pipe materials with diameters ranging from 200 to 3500mm. Using the fifth-generation equipment, the production speed is industry-leading. By simply replacing some molds, it can switch between single-wall and double-wall winding pipes, saving raw materials by 40%.

Process advantages: The main machine is an efficient single-screw extruder, with optimized screw design to ensure high-speed and high-quality extrusion; using a composite head and dual-machine joint feeding, the screw rotation molding process ensures product stability; supporting "turnkey" projects, providing a complete process formula.

PE plastic steel winding pipe production line

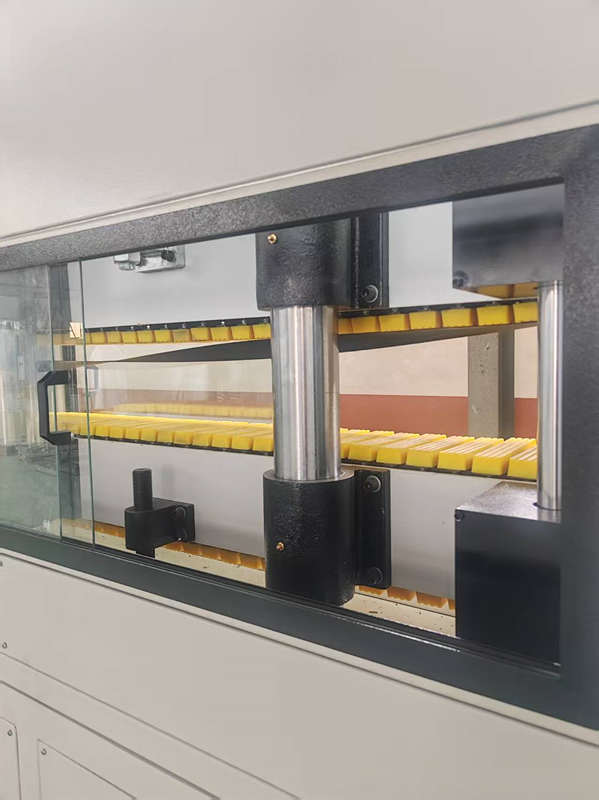

Product characteristics: The pipe materials after composite molding have stable structural dimensions, uniform and flat coating, and the equipment has the characteristics of fast production speed, wide range, high qualification rate, intermittent production capability, small floor area, and low production cost.

Equipment positioning: Also known as PE steel-plastic composite pipe equipment, it is designed with advanced technology and fine workmanship, suitable for scenarios with high requirements for pipe material structural stability.

Company strength and technical support

Enterprise qualifications and production capacity

Qualification certification: The "Changjie" trademark has been registered, and it has passed the GB/T19001-2000idtISO9001:2000 quality system certification.

Research and patents: Independently developed PPH continuous winding tank equipment and continuous winding cone equipment, with core patent technologies such as the entire-round clamping device, which can prevent the elliptical detachment of large-diameter (diameter > 2500mm, length > 3 meters) tanks.

Production scale: Established in 2000, the land area and annual output value rank among the top in the industry, capable of producing multiple sets of winding pipe equipment, and being the first enterprise in China with the manufacturing capability of continuous winding Krall pipe production line.

Industry position and market value

Replacement advantages: In response to the shortcomings of traditional cement pipes' unstable chemical properties and the high construction costs of cast iron pipes, the company's winding pipe products are regarded as ideal updated products, with huge market potential.

Technical barriers: Core equipment such as the winding tank whole-round clamping device is a patented technology. Unauthorized production or use is an infringement, effectively guaranteeing product quality and user rights.