The following are the key control strategies and methods based on multiple industry practices and theoretical summaries:

Preventive Quality Control

1. Inspection of the start-up conditions

· Pre-operation inspection: Calibrate the accuracy of equipment such as tooling, fixtures, cutting tools, and measuring tools to ensure they meet the process requirements.

During operation inspection: Real-time monitoring of the equipment's operating status, tool wear, and the cleanliness of the positioning surface.

· Post-operation inspection: Count the number of times the measuring tools are used to avoid errors caused by excessive use.

· Abnormal handling: When an abnormality is detected, the machine should be stopped immediately for adjustment. If the equipment jumps out of tolerance, it needs to be replaced, or a warning sign should be hung temporarily to mark and isolate suspicious products.

2. First item inspection

After the first piece of each process is processed, the operator must follow the standard. Measure and record the actual dimensions item by item. If they are not qualified, adjust the tooling until they meet the standards to avoid batch scrapping.

When new products or process changes occur, they need to be sent to the metrology room for testing.

And keep the records as the benchmark for subsequent production.

3.4M Change Management

· Personnel (Man): New employees need focused training. Skilled employees can only be confirmed after the first piece is qualified and the continuous processing is stable.

Equipment (Machine): After the repair, the first piece of the equipment must be qualified and five consecutive pieces must be processed for confirmation.

· Material: When the supplier changes or the material status is abnormal, the production line needs to be shut down for assessment.

· Method: The adjustment of process parameters requires advance training and a one-week tracking of the first-piece qualification rate.

Process monitoring and real-time control

1.The three-inspection system (self-inspection, mutual inspection, and special inspection)

· Self-check: The operator conducts a self-check according to the standard and finds any abnormalities. Often make immediate adjustments.

· Mutual inspection: The next process re-inspects the products of the previous process to prevent. Defective products flow into the subsequent stages.

· Specialized Inspection: Quality inspectors use precision instruments for final inspection to ensure the objectivity and fairness of the results.

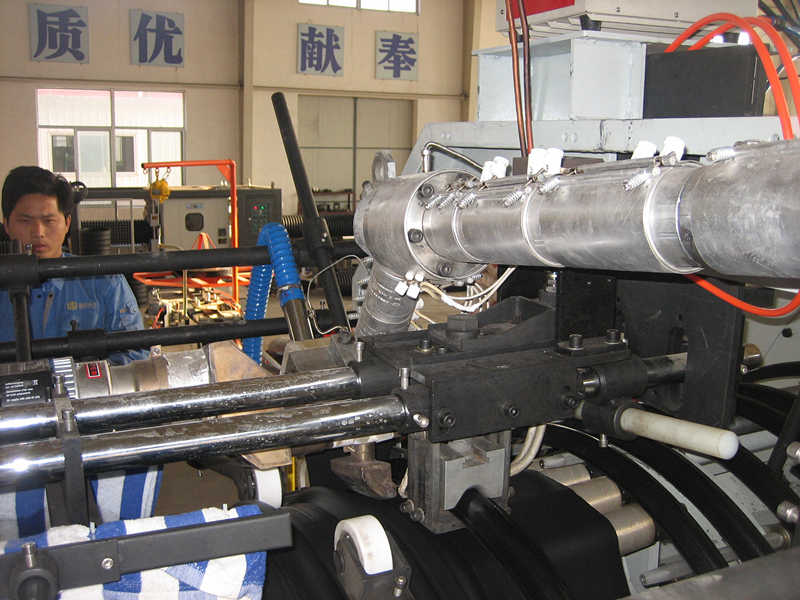

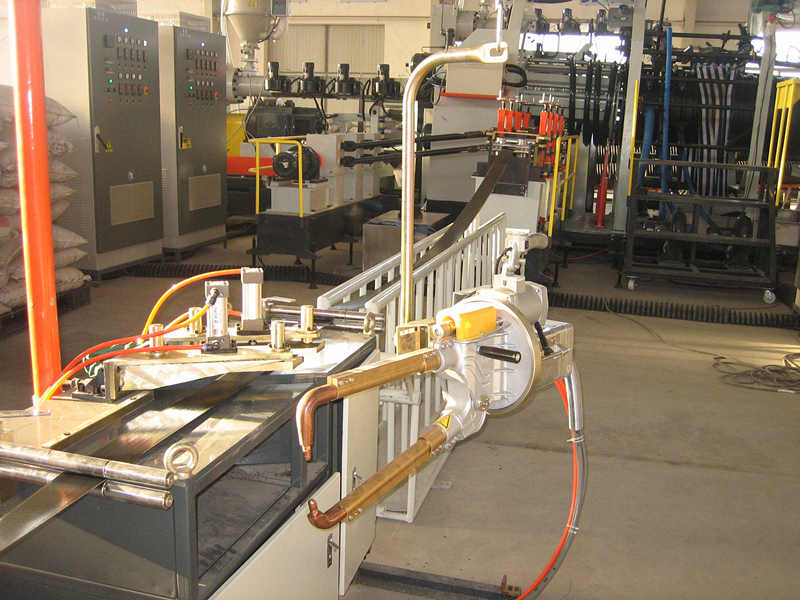

2. Online monitoring and automated detection

·Real-time collection of parameters such as temperature and pressure through sensors, combined with SPC(Statistical Process Control) analysis of process stability, and identification of abnormal fluctuations.

·Automated inspection is achieved by adopting technologies such as machine vision and sensors to enhance accuracy and efficiency.

3. Key process control

Set quality control points for high-risk processes (such as welding and assembly), and strengthen equipment maintenance and parameter monitoring.

Technical Tools and Data Analysis

1.Application of quality tools

·SPC(Statistical Process Control): Analyze process capabilities through control charts to reduce variations.

·FMEA(Failure Mode Analysis): Predict potential failure risks during the design stage and formulate preventive measures.

·Plato and the Stratification Method: Identify the main quality problems and classify and handle them.

2. Data-driven improvement

·Establish a quality database, analyze the types, frequencies and root causes of defects, and optimize process parameters.

·Adjust the quality standards in combination with customer feedback to form a closed-loop management.

Personnel Training and Institutional Guarantees

1.Improvement of employees' skills and awareness

·Regularly train on operation norms, quality standards and tool usage, and strengthen the concept of "not accepting, not manufacturing and not passing on defective products".

·Stimulate enthusiasm through quality competitions and incentive mechanisms (such as quality awards).

2. System and process norms

· Develop standardized operation instructions (Sops) and make them clear. Detailed operation rules for each link.

·Establish equipment maintenance plans and spare parts management to ensure equipment stability.

Continuous Improvement and Case Application

1.PDCA cycle

Plan → Do → Check → Act, continuously optimize the process.

2. Industry case references

· Automotive production line: By integrating process optimization, equipment monitoring and supply chain management through TQM(Total Quality Management), the defect rate is reduced.

· Electronic products: Automated detection and accelerated life testing are adopted to ensure reliability.

Summary

The quality control of the production line needs to integrate preventive management, real-time monitoring, technical tools and personnel capability improvement to form a full-cycle closed loop from design to delivery. Enterprises can combine their own characteristics and select applicable methods (such as SPC, FMEA) through data, and achieve quality goals through analysis and continuous improvement.